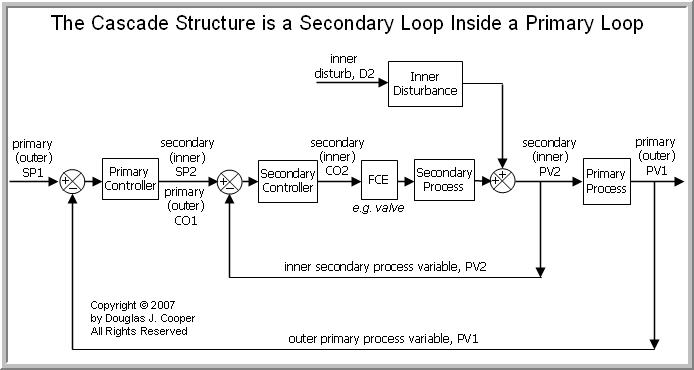

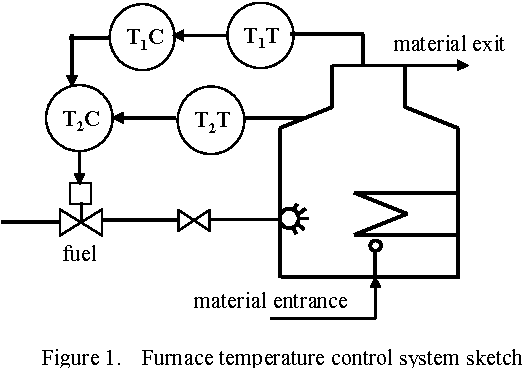

The cascade control block diagram shows a generic cascade control system with two controllers two sensors and one actuator acting on two processes in series.

Pid controller cascade process control system.

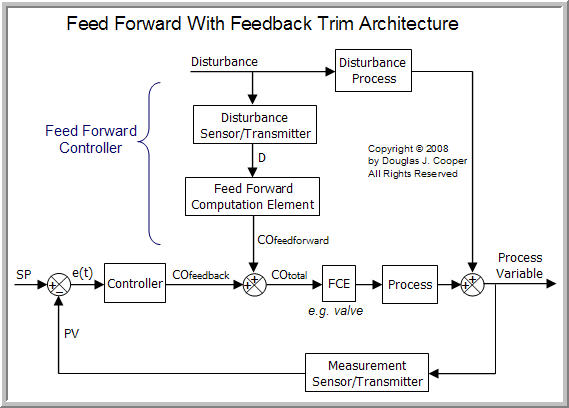

Cascade control involves the use of two controllers with the output of the first controller providing the set point for the second controller the feedback loop for one controller nestling inside the other figure 13 19 such a system can give a improved response to disturbances.

We supply a diverse range of temperature controllers and control systems.

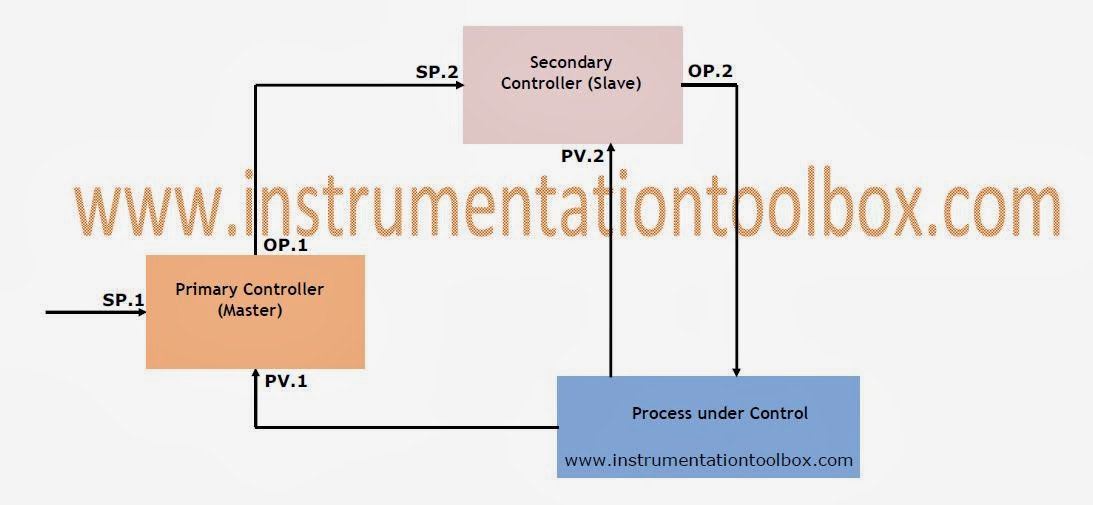

Just like supervisory control systems where a process controller receives a remote setpoint signal from some other system the secondary slave controller in a cascade system typically has three different operating modes.

We supply from miniature pid controllers to super fast process controllers for the semiconductor industry and from controllers with a stability of 0 001 c to multi zone systems of hundreds of control circuits.

Period which will quite likely affect the downstream process.

Since such systems are slow to respond to disturbances their performance can suffer with each upset.

Pid controller algorithms.

Controller takes no automatic action.

This is compared to the product temperature and the master s pid output is used to set the remote setpoint of the slave.

They also have difficulties in the presence of non linearities may trade off regulation versus response time do not react to changing process.

The product setpoint temperature is set on the master control loop.

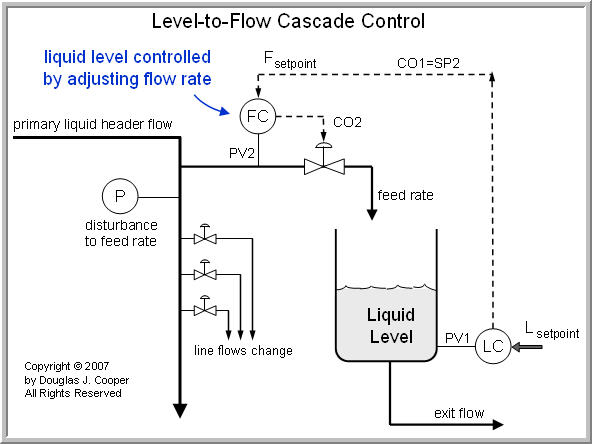

If i use cascade control system for level.

At cascade automation systems b v.

Elements of cascade control.

The cascade architecture can be applied effectively to such sluggish processes when a related and faster responding.

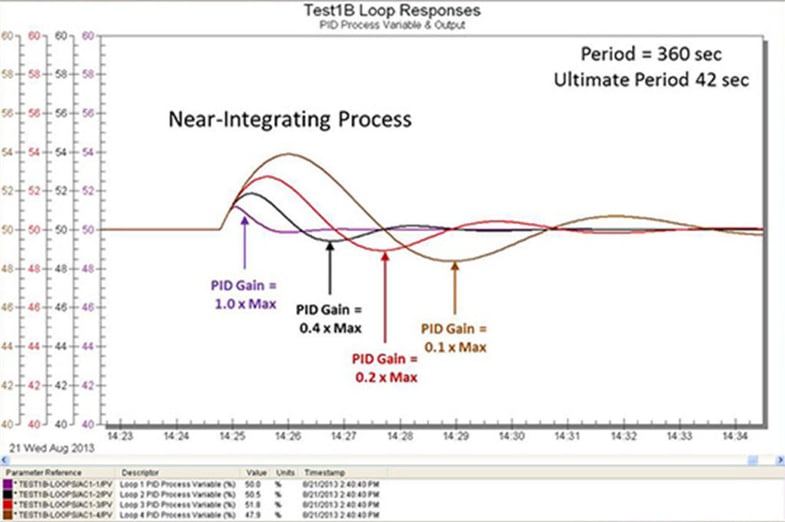

Pid controllers when used alone can give poor performance when the pid loop gains must be reduced so that the control system does not overshoot oscillate or hunt about the control setpoint value.

Controller c2 in the inner loop is the secondary controller that rejects disturbance d2 locally before it propagates to p1 for a cascade control system to function properly the inner loop must respond much faster than the outer loop.

The solution is a cascade of two or more control loops each with its own input in series forming a single regulating device.

Output value set by human operator.

1 the cascade control process is controlled by a serial based dual loop pid controller with modbus communication adam 4022t m s advantech germany which has both analog and digital inputs and outputs respectively.

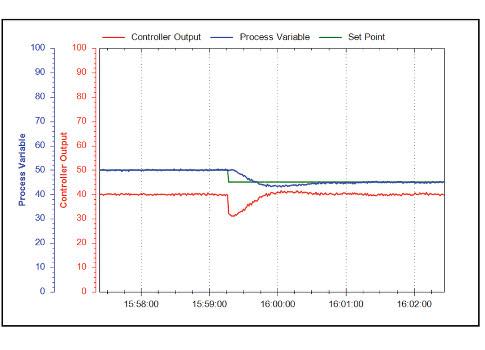

With the fast flow control loop in place the sticky control valve will cause it to oscillate but at a much shorter faster period due to the inherent fast dynamic behavior of a well tuned flow loop.

The experiment is conducted using a cascade control system which is shown in fig.